How can we help you?

Loudspeakers: A Look at Magnets

- October 17, 2017

- Comparisons Loudspeakers

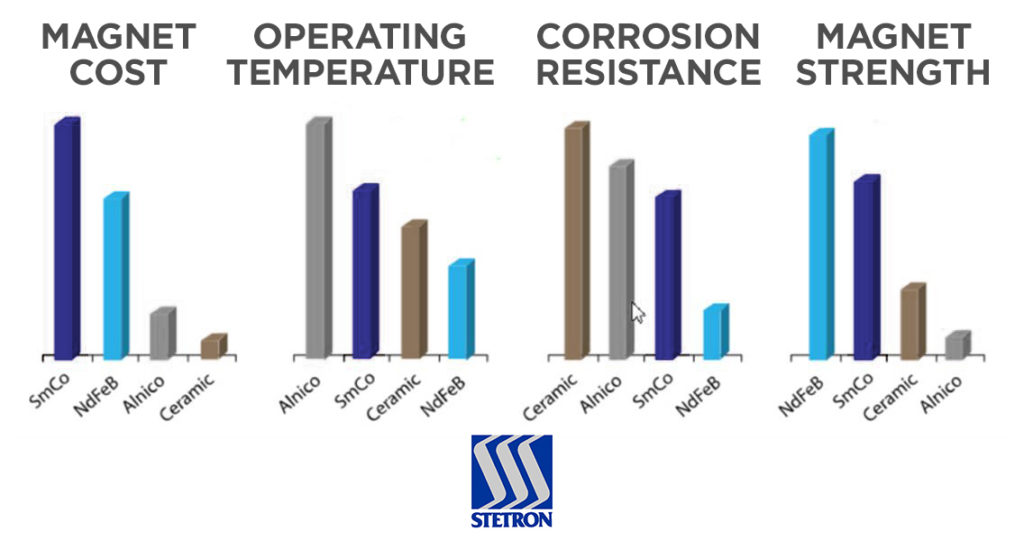

When designing a loudspeaker, several parameters must be considered, not the least of which is the magnet. Different materials provide unique characteristics that vary to meet different application needs. Some common needs are summarized in the chart below.

Anyone pulling apart their stereo speakers in the 70s or 80s is likely familiar with the traditional ceramic ferrite magnet – that charcoal grey donut sandwiched between the speaker basket and a rear plate. The low cost of raw material allows for larger magnet size to offset its relatively low magnet strength and its inherent corrosion resistance reduces the need for additional treatment needed in harsher environments. Most ceramic magnet structures in loudspeakers are open magnetic circuits, leading to significant leakage of magnetic fields in the region around the magnet. Historically, this was a significant challenge for audio-visual systems as this leakage led to image distortion in TVs. With the advent of LCD and LED flat panel televisions, the challenge of magnetic leakage is diminished but the challenge of reduced size dominates. Large, costly, shielded magnet structures were often necessary to meet this challenge.

For drivers in tight spaces, aluminum-nickel-cobalt (Al-Ni-Co) alloys traditionally provided the space savings required. The use of closed magnetic circuits offset the reduced magnet strength when compared with ceramic. Of the four main magnet materials, Al-Ni-Co has the highest Curie point, the temperature at which a magnetic material loses its permanent magnetic properties.

In the 90s, the drop-in material costs made rare earth magnets an attractive option. Neodymium alloys (e.g. Nd-Fe-B) are now ubiquitous. Those tiny fridge magnets capable of holding several times their mass are often neodymium alloys. Of all magnetic materials usually considered for loudspeakers, this alloy has the biggest magnetic punch in its weight class. Its ratio of magnetic field strength vs. size despite the additional cost over Al-Ni-Co keep it a very strong contender. Similarly, closed magnetic circuit designs provide the low leakage with an even smaller footprint, where space is at a premium.

One of the limitations of rare earth materials is their relatively low Curie point. One option is a samarium-cobalt (Sm-Co) alloy. The key factor is the rather expensive cobalt, which provides magnetic stability at higher temperatures – one of the factors providing Al-Ni-Co alloys the with the highest Curie point. While this is the costliest magnetic material, its across-the-board performance (relative magnet strength, corrosion resistance, and operating temperature) make it worthy of consideration under more extreme operating conditions.

Have questions? Let us help. We are your source for audio solutions.

Email: contact@Stetron.com

Customer Service: Canada: 1-877-716-0751 U.S.A: 1-800-925-3002.

Log In

Log In Register

Register Favorites

Favorites