How can we help you?

Loudspeakers: A Look at Mylar and Santoprene

- September 13, 2017

- Comparisons Loudspeakers

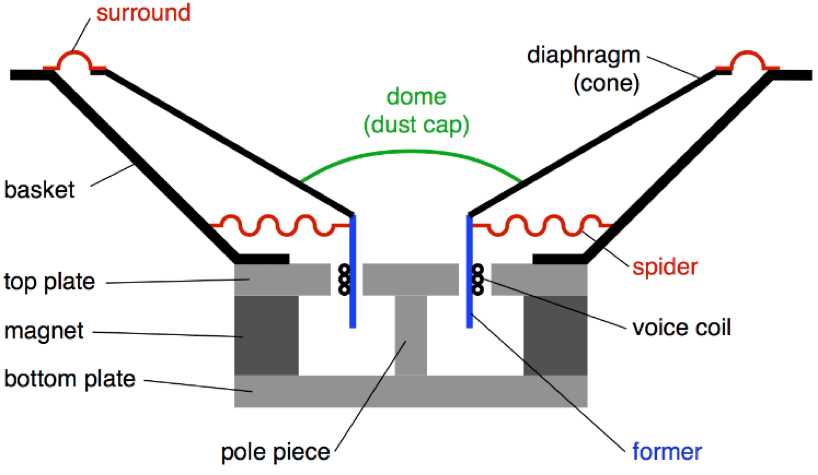

Likely the widest array of building materials in loudspeakers arises in the choice for the diaphragm (cone), surround, and gasket. These choices yield subtle but profound differences in acoustic performance. They can affect key design outcomes like Thiele-Small parameters and high frequency rolloff, or address performance concerns in different environments.

So, let’s look at the diaphragm. A common choice our customers make for cone material is paper vs. mylar. Most of us are familiar with paper as that simple sheet we write on. But paper’s not that simple – the variety in paper formulations is astounding! Different additives to the pulp mixture can be used for fine-tuning cone stiffness to control high frequency rolloff or adjusting the mass to influence resonant frequency.

In comparison, when asked, most of us would be hesitant to describe it but we’re probably as familiar with mylar as we are with paper. An alias for mylar is polyethylene terephthalate, or PET, which is used in the pedestrian water or soda bottle. A major advantage of mylar over paper comes in applications where moisture or humidity are considerations. While paper tends to absorb moisture – affecting the mass of the cone, with a resulting shift in resonance – mylar is relatively immune to this. It is also easily and consistently mouldable, making it a cost-effective solution in these applications.

Now, the diaphragm works in tandem with the surround in determining the driver’s resonant frequency among the other Thiele-Small parameters that are essential to the audio engineer. A surround can be as simple as a corrugation of the cone material at its outer edge but, if lower resonant frequency is desired, it’s common practice to make the surround from a more compliant material such as polyurethane foam, butyl rubber or santoprene. While foam gaskets tend to be more compliant, rubber is more durable. Santoprene provides a compliance in line with a foam surround with the significant improvement in durability of rubber.

So, the cone and surround materials heavily influence the Thiele-Small parameters needed to drive the enclosure design for a loudspeaker. But this can be heavily compromised if the enclosure has ill-defined air leakage. Enter the gasket. This must be a material that can conform to any surface variance where the basket of the driver meets the enclosure wall. A well-considered gasket will minimize air leaks at this critical interface. Here, the usual suspects are similar to the surround materials, with Santoprene filling that compliant but durable niche.

Have questions? Let us help. We are your source for audio solutions.

Email: contact@Stetron.com

Customer Service: Canada: 1-877-716-0751 U.S.A: 1-800-925-3002.

Log In

Log In Register

Register Favorites

Favorites